Head Quarter

| Trade name | Matsumaru, INC. |

|---|---|

| Address | Head Office: YUKEN Hirakawa-cho Bld.5F , 2-14-7 , Hirakawa-cho , Chiyoda-ku , Tokyo , 102-0093 , Japan > MAP TEL. +81-80-3715-2875 FAX. +81-3-6804-3621 New York Office: 60 Riverside Blvd #1705, New York, NY 10069, USA |

| Establishment | June 1956 |

| Capital | 40 million yen |

| President | Kiichiro Matsumaru |

| Business lineup | Manufacture of a total lineup of clothing |

| Main partner companies | sacai, Aquascutum, MARGARET HOWELL, MACKINTOSH, UNITED ARROWS, Theory, |

| Member organization | Tokyo Knit Fashion Association Tokyo Chamber of Commerce and Industry The Distribution Systems Research Institute |

Factory

Miyagi Factory

The old factory was completely destroyed by a Tsunami in 2011, but operations commenced in a new factory built in February of the following year.

This is One of the most state-of-the-art factories in Japan, featuring the latest technology and equipment.

■ Lineup of items

- General cut and sewn

- Fabric cloth pants

- Fabric cloth skirts

Location: 4-2-39 Okaido-Higashi, Ishinomaki City, Miyagi Prefecture

TEL:0225-93-8230

Outline of facilities

See the separate sheets for details.

| Process | Machine type | Number of units |

|---|---|---|

| Cutting | CAD system | 1 |

| Plotter machine | 1 | |

| CAM cutting machine | 1 | |

| Sponging machine | 1 | |

| Steric cutting machine | 3 | |

| Automatic spreading machine | 1 | |

| Spreading table | 2 | |

| Pin insertion table | 1 | |

| Sewing | Lockstitch sewing machine | 55 |

| Lock sewing machine | 36 | |

| 3-needle sewing machine | 23 | |

| Special sewing machine | 16 | |

| Intermediate process ironing | 11 | |

| Fusing press roller | 2 | |

| Finishing, inspection | Finishing iron set | 5 |

| Needle detector | 1 |

Factory introduction

-

The former Miyagi factory was completely destroyed by the tsunami on March 11, 2011. The factory was located in Ishinomaki City, a calm seaside town deep on the rias coast.

THE Three-story factory at altitude of 10 meters was nearly 20 meters above sea level up to the roof, but THE TSUNAMI height of 25 meters hit the factory.

The factory was completely destroyed and one precious employee was killed.Fortunately, the other employees were miraculously safe, so we began transferring them to the Niigata factory the following week. After about two weeks, we were able to complete the move and secure housing in Niigata to work.

This quick response was featured and introduced on Niigata TV and newspapers. One year later, the New Miyagi factory was rebuild. - - We are united in our efforts while thankful that we once again have a place to work following the tsunami.

- We will continue to deliver MADE-IN-JAPAN products from Miyagi.

- - In the new factory, state-of-the-art manufacturing facilities have been installed to improve productivity.

- We value the spaciousness of our work place while providing maximum productions within this space. - - We keep a thoroughly clean environment by cleaning twice a day so as to prevent yarn waste and dust from adhering to products.

- - We handle a wide variety of items from cut and sewn to fabric cloth, and manufacture high quality and short cycle products unique to domestic factories.

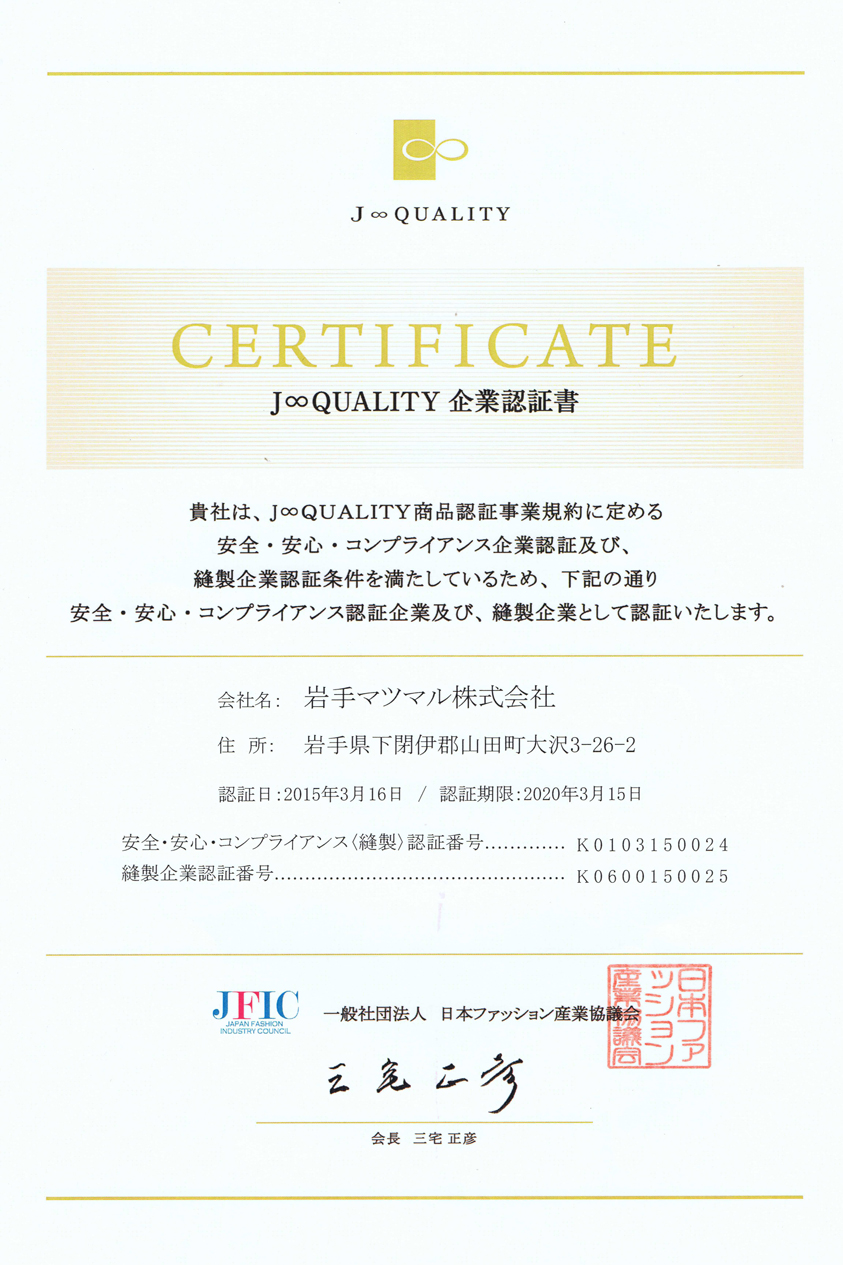

Iwate Factory

The predecessor of this factory, Iwate Sanyo Sewing, was a subsidiary of SANYO SHOKAI.

This is a “Japan quality certified factory” specializing in the production of heavy clothing and jackets including trench coats.

■ Lineup of items

- Coats

- Jackets

- One-piece

Location: 3-26-2 Osawa, Yamada-machi, Shimohei-gun, Iwate Prefecture

TEL:0193-82-5111

Outline of facilities

See the separate sheets for details.

| Process | Machine type | Number of units |

|---|---|---|

| Cutting | CREACOMPO | 5 |

| Marking plotter | 2 | |

| Pattern plotter | 1 | |

| CAM | 1 | |

| Fusing press machine | 3 | |

| Cold adhesion press machine | 1 | |

| Sewing | One-needle final stitching sewing machine | 90 |

| Overlock | 16 | |

| Blind stich sewing machine | 9 | |

| Final stitching differential up/down feed sewing machine | 12 | |

| Final stitching 2-needle sewing machine | 8 | |

| Iron finish table | 16 | |

| Binding automatic machine | 2 | |

| Final stitching unison feed sewing machine | 9 | |

| Star stich sewing machine | 6 | |

| Press, iron | Iron flat table | 6 |

| Collar press | 1 | |

| All-purpose press | 1 | |

| Sleeve cap press | 2 | |

| Genkotsu press | 1 | |

| Human body press | 1 | |

| Modular finishing machine | 1 | |

| Inspection facilities | Needle detector (conveyor type) | 2 |

| Needle detector (desktop) | 1 |

Factory introduction

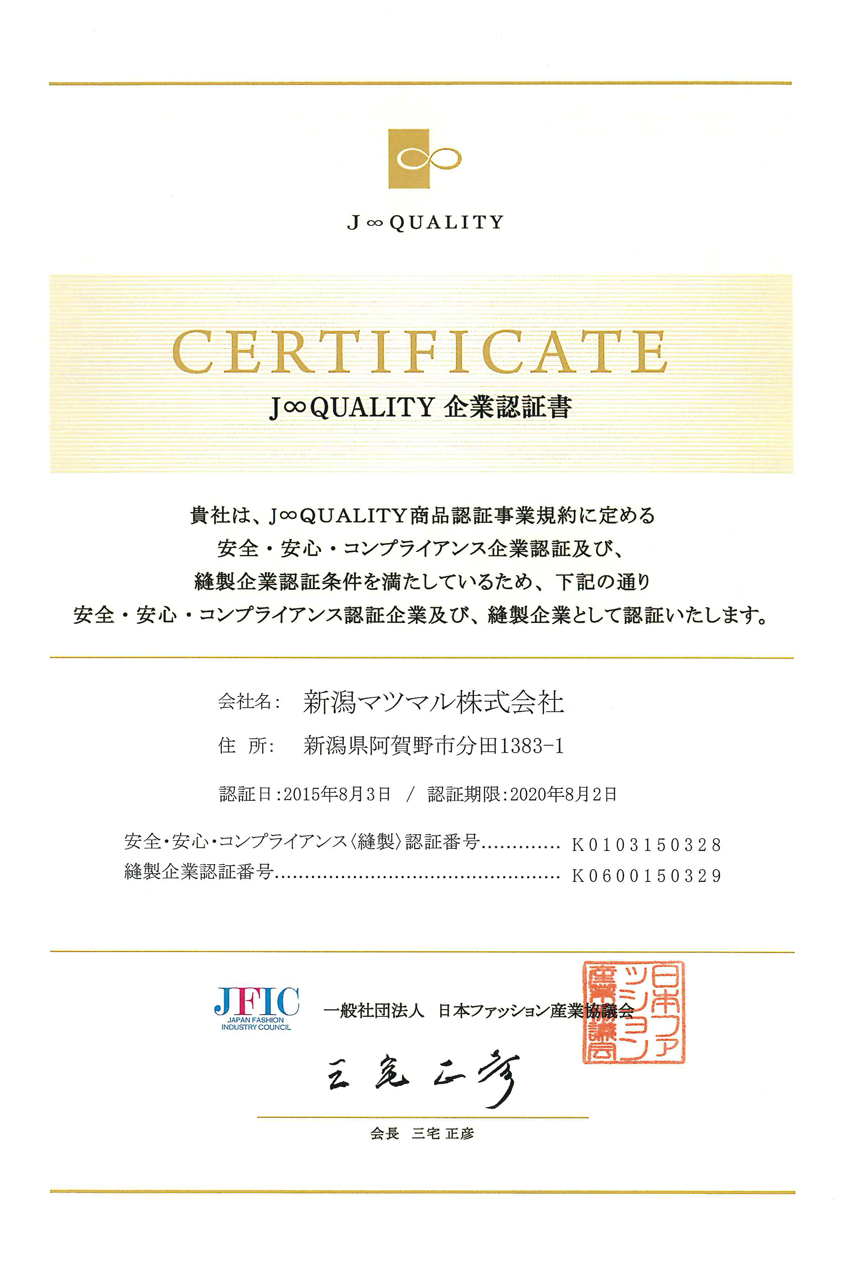

Niigata Factory

The predecessor of this factory, Niigata Sanyo Sewing, was a subsidiary of SANYO SHOKAI.

This is a “Japan quality certified factory” which can handle a wide variety of items from medium and light clothing to cut and sewn including jackets and blouses.

■ Lineup of items

- Jackets

- One-piece

- Skirts

- General cut and sewn

1383-1, Bunda, Agano City, Niigata Prefecture

TEL:0250-62-5358

Outline of facilities

See the separate sheets for details.

| Process | Machine type | Number of units |

|---|---|---|

| Cutting | CREACOMPO | 4 |

| Vertical plotter | 1 | |

| Horizontal plotter | 1 | |

| CAM | 1 | |

| Sponging machine | 3 | |

| Spreading machine | 3 | |

| Fabric inspection machine | 1 | |

| Hand knife | 2 | |

| Sewing | One-needle final stitching sewing machine | 81 |

| Differential sewing machine | 16 | |

| Lock sewing machine | 54 | |

| 3-needle sewing machine | 29 | |

| Zigzag sewing machine | 4 | |

| Pattern seamer | 4 | |

| Surging | 5 | |

| Running stich | 4 | |

| Blind stich sewing machine | 1 | |

| Deep cup seaming machine | 1 | |

| Other | 74 | |

| Press, iron | Iron vacuum table with boiler | 15 |

| Iron vacuum table | 8 | |

| Collar label press machine | 1 | |

| Auxiliary press machine | 2 | |

| Upper sleeve press machine | 1 | |

| Arm hole press machine | 1 | |

| Other irons | 19 | |

| Inspection facilities | Belt conveyor type needle detector | 2 |

| Desktop type needle detector | 1 | |

| Handy type needle detector | 1 | |

| Body | 30 |

Factory introduction

- - This factory has many veterans as well as young factory workers, who make great efforts as a team to increase the level of technical skill.

- - We employ a highly consistent process from sample to mass production in providing our high precision products, while paying great attention to detailed specifications.

- - We handle a wide range of items from cut and sewn to fabric cloth jackets.

- - We maintain high quality production while keeping in mind products unique to domestic production.

Sekikawa Factory

Sekikawa Factory specialized in men’s cut and sewn golf shirts (neckband) and polo shirts.

Later, we expanded items to ladies clothing.

The Sekikawa Factory features original sewing techniques created by the craftsmanship of experienced persons in charge of maintenance, such as modifications of sewing machines and creation of special attachments. This factory is also capable of handling unprecedented sewing specifications by creating dedicated attachments and wrappers.

■ Lineup of items

- General cut and sewn (PO, SK, PT, OP, KD)

- Combination items with fabric cloth

123-4 Shimoseki, Sekikawa-mura, Iwafune gun, Niigata Prefecture

TEL:0254-64-2261

Outline of facilities

See the separate sheets for details.

| Process | Machine type | Number of units |

|---|---|---|

| Cutting | CAD system | 1 |

| Plotter machine | 1 | |

| Actual size marker | 1 | |

| Sponging machine | 1 | |

| Servo cutter | 1 | |

| Steric cutting machine | 3 | |

| Automatic spreading machine | 1 | |

| Spreading table | 2 | |

| Pin insertion table | 1 | |

| Sewing | Lockstitch sewing machine | 77 |

| Lock sewing machine | 62 | |

| 3-needle sewing machine | 30 | |

| Special sewing machine | 34 | |

| Intermediate process ironing | 11 | |

| Fusing press roller | 3 | |

| Finishing, inspection | Finishing iron set | 4 |

| Needle detector | 3 |

Factory introduction

- - This factory has experienced skilled workers and persons with craftsmanship in charge of maintenance.

- - This factory is equipped with various sewing machines such as special sewing machines which are no longer manufactured.

- - This factory has multi-head embroidery machines, that allow for embroidery in factory.

- This factory responds to quick delivery times in a low cost manner.

- - As this factory previously sewed men’s golf shirts, the production lines demonstrate expertise at sewing shirts with collars and polo shirts.

Flow of production

Flow of production

Sponging, spreading, cutting

About sponging, spreading, cutting

- Fabric is sponged (heated and steamed) to stabilize without damaging the texture of fabric and prevents form change at the product stage.

- Clothing is spread one-by-one by automatic spreading machine while stretching wrinkles.

- This factory adopted state-of-the-art CAM technology not only for pursuit of productivity but also for cutting accuracy.

- Cutting as shown in CAD patterns cannot be imitated by manual cutting.

- For boarder and patterned cutting, fabric is spread by pin insertion and joint fixation and then carefully cut three-dimensionally.

Embroidery, sewing

About embroidery, sewing

- Sewing line of one sheet flow standing sewing machine

- There are 4 to 5 persons in one group of the cut and sewn line and 10 to 15 persons in one group of the fabric cloth line.

- Since inspection can be conducted from the first one sheet, this factory can respond to high quality and short cycles.

- In addition, this factory has embroidery machines, which allow for embroidery in the factory.

- The machining room makes machine improvements and adds special attachments in the machining room.

Inspection, finish, shipment

About inspection, finish, shipment

- Products are passed throughout the inspection process after sewing completion and checked under strict observation.

- In the finishing process, products are carefully finished one by one while adjusting the steam volume and iron temperature according to the respective product specifications.

- Products are passed through needle detectors, and can be shipped after checking for no needle mixing.